Aluminum I-Beams are a highly versatile structural material used in a variety of industries. They are essential for constructing essential infrastructure like bridges, buildings, and other forms of construction. They are also ideal for making frames for industrial machinery, vehicles, and equipment.

However, figuring out the right size chart of aluminum I beams can be quite confusing, especially for those who are not familiar with the material. Fortunately, understanding the sizing process can be easy, and with the right information, anyone can find the perfect-size I beams for their project. So, let’s dive into the sizing process to make your work a little easier!

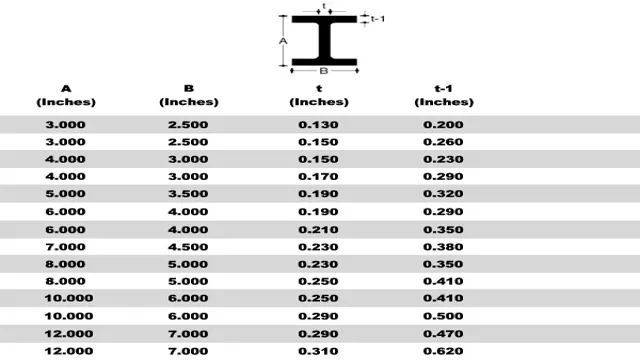

Aluminum i-Beam Size Chart

| Depth | Width | Weight per Foot | Area | Flange Thickness | Web Thickness | Fillet Radius | Axis X-X | Axis Y-Y | ||||

| I | S | r | I | S | r | |||||||

| in | in | lb. | in2 | in | in | in | in4 | in3 | in | in4 | in3 | in |

| 3.00 | 2.50 | 1.637 | 1.392 | 0.20 | 0.13 | 0.25 | 2.24 | 1.49 | 1.27 | 0.52 | 0.42 | 0.61 |

| 3.00 | 2.50 | 2.030 | 1.726 | 0.26 | 0.15 | 0.25 | 2.71 | 1.81 | 1.25 | 0.68 | 0.54 | 0.63 |

| 4.00 | 3.00 | 2.311 | 1.965 | 0.23 | 0.15 | 0.25 | 5.62 | 2.81 | 1.69 | 1.04 | 0.69 | 0.73 |

| 4.00 | 3.00 | 2.793 | 2.375 | 0.29 | 0.17 | 0.25 | 6.71 | 3.36 | 1.68 | 1.31 | 0.87 | 0.74 |

| 5.00 | 3.50 | 3.700 | 3.146 | 0.32 | 0.19 | 0.30 | 13.94 | 5.58 | 2.11 | 2.29 | 1.31 | 0.85 |

| 6.00 | 4.00 | 4.030 | 3.427 | 0.29 | 0.19 | 0.30 | 21.99 | 7.33 | 2.53 | 3.10 | 1.55 | 0.95 |

| 6.00 | 4.00 | 4.692 | 3.990 | 0.35 | 0.21 | 0.30 | 25.50 | 8.50 | 2.53 | 3.74 | 1.87 | 0.97 |

| 7.00 | 4.50 | 5.800 | 4.932 | 0.38 | 0.23 | 0.30 | 42.89 | 12.25 | 2.95 | 5.78 | 2.57 | 1.08 |

| 8.00 | 5.00 | 6.181 | 5.256 | 0.35 | 0.23 | 0.30 | 59.69 | 14.92 | 3.37 | 7.30 | 2.92 | 1.18 |

| 8.00 | 5.00 | 7.023 | 5.972 | 0.41 | 0.25 | 0.30 | 67.78 | 16.94 | 3.37 | 8.55 | 3.42 | 1.20 |

| 9.00 | 5.50 | 8.361 | 7.110 | 0.44 | 0.27 | 0.30 | 102.02 | 22.67 | 3.79 | 12.22 | 4.44 | 1.31 |

| 10.00 | 6.00 | 8.646 | 7.352 | 0.41 | 0.25 | 0.40 | 132.09 | 26.42 | 4.24 | 14.78 | 4.93 | 1.42 |

| 10.00 | 6.00 | 10.286 | 8.747 | 0.50 | 0.29 | 0.40 | 155.79 | 31.16 | 4.22 | 18.03 | 6.01 | 1.44 |

| 12.00 | 7.00 | 11.672 | 9.925 | 0.47 | 0.29 | 0.40 | 255.57 | 42.60 | 5.07 | 26.90 | 7.69 | 1.65 |

| 12.00 | 7.00 | 14.292 | 12.153 | 0.62 | 0.31 | 0.40 | 317.33 | 52.89 | 5.11 | 35.48 | 10.14 | 1.71 |

What is an I Beam?

An I beam, also known as an H beam, is a steel or aluminum beam shaped like the letter “I” or “H”. It is commonly used in construction projects as structural support for buildings and bridges. The unique shape of the I beam allows it to distribute weight evenly across its length, making it an ideal choice for structures that require a strong and stable foundation.

When it comes to choosing the right size of aluminum I beam for your project, it’s important to consider factors like the weight of the load, the length of the span, and the distance between the supports. By referring to an aluminum I beam size chart, you can find the ideal size and weight capacity for your specific application. Whether you’re building a new home or a massive skyscraper, an I beam is an essential component that provides both strength and stability to your structure.

Explanation of I-beams and their uses.

An I beam is a structural component that is commonly used in construction due to its strength and durability. It gets its name from its distinctive shape, which resembles the capital letter “I”. The design of an I beam allows it to distribute weight evenly across its length and resist bending or warping.

This makes it ideal for use in load-bearing structures such as bridges, skyscrapers, and industrial buildings. Additionally, because of their ability to support heavy loads without sagging or breaking, I beams are also used in the construction of cranes, trolleys, and other heavy machinery. Overall, the I beam is a versatile and essential component in the construction industry, used to support and sustain many different types of structures.

Aluminum Alloy Options

One of the most popular questions that people ask when it comes to aluminum I-beams is about their size chart. Well, the good news is that aluminum I-beams come in a variety of sizes that are designed to suit different applications. The size chart for aluminum I-beams ranges from 3 inches to 24 inches in height.

This means that you can find an aluminum I-beam that will fit your project perfectly. Each size of aluminum I-beam comes with its own load-bearing capacity, so it’s important to choose the right size for your specific project. Additionally, there are different aluminum alloy options available for I-beams that you can choose from depending on the specific application, environment, and load requirements.

These include 6061-T6 and 6063-T5 aluminum alloys, which both offer excellent strength-to-weight ratios and are corrosive-resistant. With such a wide range of sizes and alloy options, aluminum I-beams are highly versatile, making them an excellent choice for a wide array of structural projects.

Overview of common aluminum alloys used for I beams.

When it comes to I beams, aluminum alloys are a popular choice due to their lightweight, high strength, and corrosion resistance. There are several common aluminum alloys used for I beams, including 6061, 6063, and 608 6061 is the most widely used aluminum alloy for structural applications, known for its excellent machinability and weldability.

6063 is commonly used for architectural applications due to its smoother finish and better corrosion resistance. Meanwhile, 6082 has high strength and good weldability, making it suitable for heavy-duty applications. Each of these alloys has its unique properties and benefits, so it’s crucial to consider the specific requirements of the project before choosing an aluminum alloy for I beams.

Overall, aluminum alloys offer several advantages for I beams, including durability, versatility, and cost-effectiveness.

Dimensions and Sizes

When it comes to aluminum I-beams, it’s essential to have a good understanding of their sizes and dimensions before purchasing. The aluminum I-beam size chart offers a complete range of dimensions. This chart can be used to find the right size for your project, as well as ensuring that you make informed decisions.

The dimensions of these beams are usually broken down into three areas, including the web, fillet, and flange. The web is the vertical part of the beam while the fillet is where the two segments of the beam meet. The flange is the horizontal section of the beam.

Standard beam lengths tend to range from 10 feet to 40 feet. Additionally, a various range of sizes in inches is available, allowing for customization to fit specific project needs. By understanding these sizes and dimensions, you can ensure that you select the right aluminum I-beam size for your project to guarantee the desired outcomes.

Detailed chart of I beam sizes and dimensions.

If you’re in need of structural steel for your construction project, chances are you’ll come across I beams. These steel beams are widely used in construction as load-bearing members that support heavy loads. The standard I beam sizes and dimensions vary depending on the requirements of a particular project.

In general, I beams range in size from 4 inches to 44 inches in depth, with a weight capacity that can range from 7 pounds per foot up to 121 pounds per foot. The weight capacity of an I beam is determined by its size and length, so it’s essential to know the dimensions you need for your project.

It’s also important to note that I beam sizes can differ between countries, so make sure you’re looking at the right chart for your location. Use the chart as a guide to help you determine which I beam size and weight capacity is the right choice for your construction needs.

Weight and Load Capacities

An aluminum I-beam is a versatile building material that can handle significant weight loads if used correctly. However, choosing the right size and weight capacity can be confusing if you don’t have the right information. Fortunately, an aluminum I-beam size chart can help you select the right dimensions and weight capacity for your specific building project.

The chart includes information such as the beam’s width, height, and thickness, as well as information on the load capacity. A larger beam will have a greater load capacity, but it is also heavier and more expensive. It is crucial to consider the weight of the building materials and any additional load that the structure must bear, such as equipment or people, when selecting the right beam size.

This ensures that the structure can withstand the forces and weight loads placed on it. Overall, an aluminum I-beam size chart serves as an essential tool for builders, architects, and homeowners when planning and designing sturdy and stable structures.

Information on weight capacity and load limitations for each size of I beam.

When it comes to constructing with I beams, it is crucial to understand the weight and load capacities for each size. The weight capacity is simply the maximum weight that can be supported without causing structural damage, while load capacity refers to the force or pressure that can be applied to the beam. For instance, a W8x18 I beam can support up to 18,000 pounds of weight, making it suitable for small-scale construction projects.

In contrast, a W36x300 I beam can handle up to 300,000 pounds of weight, making it ideal for large-scale commercial and industrial buildings. It is essential to choose the appropriate size based on the weight and load requirements of your project. Installing a smaller beam than necessary can lead to structural failure, while using a larger beam can result in unnecessary expenses.

Therefore, consult with a structural engineer to determine the best-fit I beam for your project based on maximum weight and load requirements while ensuring it adequately fulfills safety standards.

Applications and Industries

When it comes to construction, aluminum I beams are a popular choice due to their strength and durability. However, choosing the correct size can be a bit perplexing. That’s why an aluminum I beam size chart can be a helpful tool.

These charts provide information on the dimensions and weight of each type of I beam. It’s important to consider your specific industry and application when selecting the appropriate size. For example, a larger beam may be necessary for a heavy load-bearing task, while a smaller beam may suffice for a decorative or non-load bearing application.

Industries that commonly use aluminum I beams include construction, aerospace, and marine. Overall, understanding the right size for your project can ensure efficiency and long-term stability.

Industries and applications where I beams are commonly used.

I beams, also known as H beams, are commonly used in a variety of industries and applications due to their strength and versatility. One of the most prevalent industries that utilize I beams is construction. These beams are often used to create the supportive framework in buildings, bridges, and tunnels.

They can also be found in the manufacturing industry, where they are used to support heavy machinery and equipment. I beams are especially useful in applications where weight needs to be distributed evenly, as they have a wider flange than other types of beams. In addition to their structural support capabilities, I beams are also used in the automotive industry to strengthen vehicle frames and improve overall safety.

Overall, I beams are a crucial component in many industries and provide reliable support for a wide range of applications.

Conclusion

In conclusion, the aluminum I beam size chart is like a guidebook for the modern-day engineer, providing a roadmap of options to choose from when building structures. It’s like a culinary recipe book for construction, with each beam size serving as a different ingredient that can be mixed and matched to create a versatile array of designs. So when it comes to crafting sturdy, sleek and sustainable structures, let this chart be your trusty sous chef in the kitchen of building design!”

FAQs

What are the standard sizes available for aluminum I-beams?

Aluminum I-beams commonly come in standard sizes ranging from 3 inches to 12 inches for the height and from 1.5 inches to 4.5 inches for the flange width.

What is the weight range for different aluminum I-beam sizes?

The weight of aluminum I-beams varies depending on their size. The weight range for different aluminum I-beam sizes usually starts from 1.20 pounds per foot to 16.40 pounds per foot.

Can aluminum I-beams be cut to fit a specific length?

Yes, aluminum I-beams can be cut to fit a specific length as per your requirements.

What are the advantages of using aluminum I-beams in construction?

Aluminum I-beams offer several advantages in construction, such as high strength-to-weight ratio, resistance to corrosion, lightweight, and durability. These properties make them suitable for use in various applications and industries, especially where weight reduction is crucial.