If you’re in the market for high-density polyethylene (HDPE) pipes, you’ll want to know about DIPS, or “ductile iron pipe size,” which is a standardized system used to measure pipe diameter. With so many different size options available, it can be tough to determine which one is the right fit for your project. That’s where an HDPE DIPS Pipe Size Chart comes in handy! This valuable resource provides all the necessary information you need to choose the right HDPE pipe size.

Consider this chart your roadmap to success as you navigate the world of HDPE pipes. But before we delve into this topic, let’s first discuss what HDPE pipes are and the benefits they offer over other types of pipes.

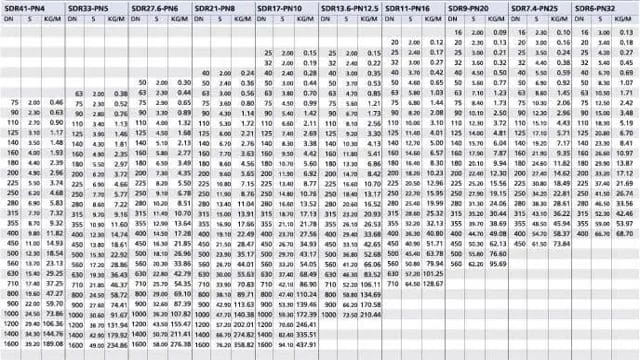

HDPE DIPS Pipe Size Chart

| Nominal Pipe Size DIPS (Known as Inches) | Real Size Outside Diameter (OD) (Inches) | Real Outside Diameter (OD) (mm) 1 Inch = 25.4 mm |

| 3″ DIPS | 3,96 in. | 100.584 mm |

| 4″ DIPS | 4.8 in. | 121.92 mm |

| 6″ DIPS | 6.9 in. | 175.26 mm |

| 8″ DIPS | 9.05 in. | 229.87 mm |

| 10″ DIPS | 11.1 in. | 281.94 mm |

| 12″ DIPS | 13.2 in. | 335.28 mm |

| 14″ DIPS | 15.3 in. | 388.62 mm |

| 16″ DIPS | 17.4 in. | 441.96 mm |

| 18″ DIPS | 19.5 in. | 495.3 mm |

| 20″ DIPS | 21.6 in. | 548.64 mm |

| 24″ DIPS | 25.8 in. | 655.32 mm |

| 30″ DIPS | 32 in. | 812.8 mm |

| 36″ DIPS | 38.3 in. | 972.82 mm |

| 42″ DIPS | 44.5 in. | 1130.3 mm |

| 48″ DIPS | 50.8 in. | 1290.32 mm |

Understanding HDPE DIPS Pipe Size

The HDPE DIPS pipe size chart can be somewhat confusing to understand if you’re not familiar with the terminology. DIPS stands for “ductile iron pipe size,” which means that the pipe is sized based on the outside diameter of the ductile iron pipe that it would fit inside of. So, for example, if you were looking at a 2-inch DIPS HDPE pipe, that would mean that the outside diameter of the pipe is 2 inches.

It’s important to note that the actual internal diameter of the pipe will be smaller due to the thickness of the pipe walls. This is where burstiness comes in – the thickness of the walls makes the pipe more resistant to burst or cracking under pressure. So, while the HDPE DIPS pipe size chart may seem a bit confusing at first, it’s actually a reliable way to ensure that you’re selecting the right pipe for your project.

What is HDPE DIPS Pipe?

HDPE DIPS Pipe HDPE DIPS Pipe, also known as High-Density Polyethylene Ductile Iron Pipe Size, is a type of durable piping material used for various applications such as water distribution, gas transportation, and sewage disposal. Unlike traditional pipes made of metal, HDPE pipes are lightweight, flexible, and have better resistance to corrosion, abrasion, and chemicals. One of the most important factors to consider when selecting HDPE DIPS Pipe is its size, which is measured based on the outer diameter of the pipe.

The sizes range from 4 inches to 63 inches in diameter, and each size has its own unique application and requirement. It is important to select the appropriate size to ensure that the pipe performs optimally without any restrictions or pressure losses. Therefore, it is recommended to consult with a professional to determine the correct HDPE DIPS Pipe size for your specific application.

Why is DIPS important to know?

DIPS, HDPE DIPS Pipe Size DIPS stands for “ductile iron pipe size” and is an important term to know when it comes to understanding HDPE (high-density polyethylene) pipe sizes. HDPE pipes are a popular choice for a variety of applications because of their durability, flexibility, and resistance to corrosion. But, understanding the different pipe dimensions and sizes can be confusing.

This is where the DIPS standard comes in handy. DIPS is a standardized system of measuring pipes, originally developed for ductile iron pipes. However, the term is now commonly used to describe the size of HDPE pipes as well.

The DIPS measurements are based on the internal diameter (ID) of the pipe, rather than the outside diameter (OD) like other pipe measurement systems. This means that pipes with the same DIPS size may have different outside diameters, depending on the wall thickness of the pipe. Knowing the DIPS size of an HDPE pipe is important for selecting the correct fittings and valves, as well as correctly sizing the pipe for the specific application.

It can also help ensure that the pipe is compatible with any existing piping system that utilizes the DIPS standard. In conclusion, understanding DIPS is crucial to understand HDPE pipe sizes, and this knowledge will help in selecting the right pipe size, fittings, and valves for any application.

HDPE DIPS Pipe vs IPS Pipe Sizes

HDPE DIPS Pipe If you are looking for high-density polyethylene (HDPE) pipe, you may come across two different sizing methods: DIPS and IPS. DIPS stands for “ductile iron pipe size,” while IPS stands for “iron pipe size.” The difference between the two is the wall thickness.

DIPS pipes have thicker walls and are more durable, making them suitable for underground installation and high-pressure applications. DIPS pipe size is measured in inches and corresponds to the outside diameter of the pipe. For example, a 4-inch DIPS pipe has an actual outside diameter of

5 inches. This is because the wall thickness is added to the outer diameter measurement. DIPS pipes are typically used for gas and water distribution, irrigation, and sewage systems.

IPS pipe size, on the other hand, is measured in nominal size and corresponds to the inside diameter of the pipe. For example, a 4-inch IPS pipe has an actual outside diameter of 5 inches, but an inside diameter of only 4 inches.

IPS pipes are typically used for above-ground installation and low-pressure applications. In summary, understanding HDPE DIPS pipe size is crucial when choosing the right pipe for your application. DIPS pipes have thick walls and are suitable for underground and high-pressure applications, while IPS pipes have thinner walls and are suitable for above-ground and low-pressure applications.

Always consult with a professional before making any pipe installation decisions to ensure safety and compliance.

Interpreting the HDPE DIPS Pipe Size Chart

If you’re new to the world of HDPE DIPS pipes, the size chart can seem daunting at first. However, interpreting it is easier than you might think. The chart lists the outside diameter of the pipe in inches, as well as the corresponding SDR (Standard Dimension Ratio) and pressure rating.

It’s important to note that the SDR is not a measurement of the pipe’s thickness, but rather a ratio of the outside diameter to the wall thickness. A higher SDR means a thinner wall and larger pipe diameter, while a lower SDR means a thicker wall and smaller pipe diameter. The pressure rating, measured in pounds per square inch or PSI, indicates the maximum pressure the pipe can handle.

Overall, understanding the HDPE DIPS pipe size chart is crucial for selecting the right pipe for your project and ensuring safe, efficient operation.

Dimensions Included in the HDPE DIPS Pipe Size Chart

The HDPE DIPS Pipe Size Chart includes various dimensions to help users select the right type of pipe for their projects. The chart lists the outside diameter (OD), inside diameter (ID), wall thickness, and weight per foot of pipe. These dimensions can be a bit confusing to interpret at first, but it’s crucial to understand their significance.

The OD is the largest diameter of the pipe, while the ID is the inner diameter of the pipe. The wall thickness is the distance between the OD and ID and helps determine the strength of the pipe. The weight per foot of pipe is also important for transportation and installation purposes.

It’s essential to choose the right size based on the intended use of the pipe and the pressure and temperature requirements of the application. By understanding the dimensions included in the HDPE DIPS Pipe Size Chart, users can make informed decisions and select the right pipe for their needs.

How to Read the HDPE DIPS Pipe Size Chart

If you’re new to plumbing, you may find the HDPE DIPS Pipe Size chart a bit confusing at first glance. However, interpreting this chart is not rocket science, and we’re here to tell you how. Firstly, let’s get into what HDPE DIPS stands for.

In short, it means High-Density Polyethylene, Ductile Iron Pipe Size. This chart is a vital tool for sizing pipes. The HDPE DIPS pipe sizes vary from 2″ to 36 “inches diameters.

It is essential to understand that the DIPS size measurement is different from the nominal size. The nominal size is the approximate size of the pipe, while the DIPS size measures the internal diameter. For example, when looking at the HDPE DIPS pipe size chart, a pipe with a nominal size of 4″ will have an internal diameter of

500″. This chart is crucial in determining the size of pipe required to run a plumbing system effectively. Knowing how to interpret the chart’s information allows you to select the correct pipe size for your specific plumbing job, reducing the potential for costly mistakes.

Using the HDPE DIPS Pipe Size Chart

When working with high-density polyethylene (HDPE) pipes, it’s essential to understand the DIPS Pipe Size Chart. The chart lists the outside diameter of the pipe, the wall thickness, and the weight per foot of the pipe. This information is critical when selecting the right pipe size for your specific project.

The DIPS Pipe Size Chart is typically used for gas, oil, and other industrial applications that require durability and strength. The chart can be difficult to navigate at first, but once you understand the different measurements, it becomes much more manageable. Always consult the chart before selecting a pipe size to ensure that your project is safe and efficient.

With the right size pipe, you can rest assured that your project will be a success!

Selecting the Correct Product Size

When it comes to selecting the correct product size of HDPE DIPS pipes, it can be a bit of a challenge. Luckily, you can use the handy HDPE DIPS Pipe Size Chart to make your decision easier. This chart offers a helpful guide to identifying the correct pipe size for your project, taking into account factors like the desired flow rate and the type of material being transported.

It is important to choose the correct size to ensure optimum performance and prevent any leaks or damage. By referring to the HDPE DIPS Pipe Size Chart, you can make an informed decision and be confident that you are selecting the correct product size for your needs. So why not give it a try and save yourself time and money in the long run?

Calculating the Proper Length of Pipe Needed

When it comes to installing HDPE pipes, calculating the proper length of pipe needed is crucial. One effective way to determine the right pipe size and length is by using the HDPE DIPS Pipe Size Chart. DIPS stands for “ductile iron pipe size,” which refers to the outside diameter of the pipe.

The HDPE DIPS Pipe Size Chart lists the available sizes of HDPE pipes and their corresponding dimensions, including the outside diameter, wall thickness, and inner diameter. By measuring the distance between the starting point and endpoint of the pipeline and factoring in the elevation change and any other obstacles, you can determine the length of pipe needed using the HDPE DIPS Pipe Size Chart. This will help you select the proper size and length of HDPE pipe required for your project and avoid issues such as leaks and structural failure.

So, make sure to use this handy tool to ensure the success of your HDPE pipe installation.

Conclusion – Finding the Right HDPE DIPS Pipe Size

In conclusion, the HDPE dips pipe size chart is like a puzzle where each piece fits perfectly to create a seamless and efficient piping system. With its range of sizes and fittings, the chart allows you to find just the right fit for your project, making your job faster and easier. It’s like having a toolbox filled with just the right tools for the job – you’ll never be left searching for the right piece again.

So, whether you’re working on a large construction project or a small DIY job, the HDPE dips pipe size chart is the ultimate solution for all your piping needs.”

FAQs

What is HDPE?

HDPE stands for High-Density Polyethylene, which is a petroleum-derived thermoplastic polymer consisting of long chains of ethylene monomers.

What are dips pipes made of?

DIPS (Ductile Iron Pipe Size) pipes can be made of a variety of materials, including HDPE, PVC, and ductile iron.

What sizes are available in HDPE DIPS pipes?

HDPE DIPS pipes come in a range of sizes, from ¾-inch to 63-inch diameter.

What are some typical applications of HDPE DIPS pipes?

HDPE DIPS pipes are commonly used for water and gas distribution, sewage and drainage systems, mining, and irrigation.