When a project hinges—literally—on the right fastener, a clear bolt size chart can save time, money, and frustration. Yet every choice balances strength, weight, and budget; oversizing adds cost, and under-sizing risks failure. Therefore, understanding thread pitch, material grade, and torque limits empowers you to navigate these trade‑offs confidently and safely.

Bolt Size Chart

| Size | Nominal (Major) | Coarse Thread (UNC) | Fine Thread (UNF) | ||||

| Diameter [in] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | |

| #0 | 0.06 | — | — | — | 80 | 0.0018 | 0.0015 |

| #2 | 0.086 | 56 | 0.0037 | 0.0031 | 64 | 0.0039 | 0.0034 |

| #4 | 0.112 | 40 | 0.006 | 0.005 | 48 | 0.0066 | 0.0057 |

| #5 | 0.125 | 40 | 0.008 | 0.0067 | 44 | 0.0083 | 0.0072 |

| #6 | 0.138 | 32 | 0.0091 | 0.0075 | 40 | 0.0102 | 0.0087 |

| #8 | 0.164 | 32 | 0.014 | 0.012 | 36 | 0.0147 | 0.0129 |

| #10 | 0.19 | 24 | 0.0175 | 0.0145 | 32 | 0.02 | 0.0175 |

| 1/4″ | 0.25 | 20 | 0.0318 | 0.0269 | 28 | 0.0364 | 0.0326 |

| 5/16″ | 0.3125 | 18 | 0.0524 | 0.0454 | 24 | 0.058 | 0.0524 |

| 3/8″ | 0.375 | 16 | 0.0775 | 0.0678 | 24 | 0.0878 | 0.0809 |

| 7/16″ | 0.4375 | 14 | 0.1063 | 0.0933 | 20 | 0.1187 | 0.109 |

| 1/2″ | 0.5 | 13 | 0.1419 | 0.1257 | 20 | 0.1599 | 0.1486 |

| 9/16″ | 0.5625 | 12 | 0.182 | 0.162 | 18 | 0.203 | 0.189 |

| 5/8″ | 0.625 | 11 | 0.226 | 0.202 | 18 | 0.256 | 0.24 |

| 3/4″ | 0.75 | 10 | 0.334 | 0.302 | 16 | 0.373 | 0.351 |

| 7/8″ | 0.875 | 9 | 0.462 | 0.419 | 14 | 0.509 | 0.48 |

| 1″ | 1 | 8 | 0.606 | 0.551 | 12 | 0.663 | 0.625 |

| 1-1/8″ | 1.125 | 7 | 0.763 | 0.693 | 12 | 0.856 | 0.812 |

| 1-1/4″ | 1.25 | 7 | 0.969 | 0.89 | 12 | 1.073 | 1.024 |

| 1-3/8″ | 1.375 | 6 | 1.155 | 1.054 | 12 | 1.315 | 1.26 |

| 1-1/2″ | 1.5 | 6 | 1.405 | 1.294 | 12 | 1.581 | 1.521 |

| 1-3/4″ | 1.75 | 5 | 1.9 | 1.74 | — | — | — |

| 2″ | 2 | 4.5 | 2.5 | 2.3 | — | — | — |

Metric Bolt Thread Size

| Nominal (Major) | Coarse Pitch | Fine Pitch | ||||

| Diameter [mm] | Pitch | Tensile Stress | Minor | Pitch | Tensile Stress | Minor |

| [mm] | Area [mm2] | Area [mm2] | [mm] | Area [mm2] | Area [mm2] | |

| 1.6 | 0.35 | 1.27 | 1.076 | — | — | — |

| 2 | 0.4 | 2.073 | 1.789 | — | — | — |

| 2.5 | 0.45 | 3.391 | 2.98 | — | — | — |

| 3 | 0.5 | 5.031 | 4.473 | — | — | — |

| 3.5 | 0.6 | 6.775 | 6 | — | — | — |

| 4 | 0.7 | 8.779 | 7.75 | — | — | — |

| 5 | 0.8 | 14.18 | 12.68 | — | — | — |

| 6 | 1 | 20.12 | 17.89 | — | — | — |

| 8 | 1.25 | 36.61 | 32.84 | 1 | 39.17 | 36.03 |

| 10 | 1.5 | 57.99 | 52.29 | 1.25 | 61.2 | 56.3 |

| 12 | 1.75 | 84.27 | 76.25 | 1.25 | 92.07 | 86.04 |

| 14 | 2 | 115.4 | 104.7 | 1.5 | 124.5 | 116.1 |

| 16 | 2 | 156.7 | 144.1 | 1.5 | 167.2 | 157.5 |

| 20 | 2.5 | 244.8 | 225.2 | 1.5 | 271.5 | 259 |

| 24 | 3 | 352.5 | 324.3 | 2 | 384.4 | 364.6 |

| 30 | 3.5 | 560.6 | 519 | 2 | 621.2 | 596 |

| 36 | 4 | 816.7 | 759.3 | 2 | 914.5 | 883.8 |

| 42 | 4.5 | 1121 | 1045 | 2 | 1264 | 1228 |

| 48 | 5 | 1473 | 1377 | 2 | 1671 | 1629 |

| 56 | 5.5 | 2030 | 1905 | 2 | 2301 | 2252 |

| 64 | 6 | 2676 | 2520 | 2 | 3031 | 2975 |

| 72 | 6 | 3460 | 3282 | 2 | 3862 | 3799 |

| 80 | 6 | 4344 | 4144 | 1.5 | 4851 | 4798 |

| 90 | 6 | 5591 | 5364 | 2 | 6099 | 6020 |

| 100 | 6 | 6995 | 6740 | 2 | 7562 | 7473 |

| 110 | — | — | — | 2 | 9182 | 9084 |

Why Bolt Sizes Matter

Choosing the correct bolt size goes beyond fit; it directly affects structural integrity, safety, and service life. Moreover, the right diameter and thread pitch distribute loads evenly, thereby preventing fatigue cracks that spread silently until a joint fails.

Conversely, an oversized bolt may seem safer, yet it can concentrate stress in surrounding materials, add unnecessary weight, and inflate costs. Meanwhile, undersized fasteners save money up front but often stretch, loosen, or shear under dynamic loads, leading to costly downtime or catastrophic collapse.

Therefore, you must weigh each trade‑off—strength, weight, cost, and ease of assembly—before settling on a size. However, that decision rarely stands alone: you must also match strength grade, material, and proper torque, since even a perfectly sized bolt will fail if over‑ or under‑tightened.

Ultimately, a reliable bolt size chart brings these variables together in one place, guiding you through competing priorities and revealing how a seemingly small choice can determine the long‑term performance and safety of the entire structure.

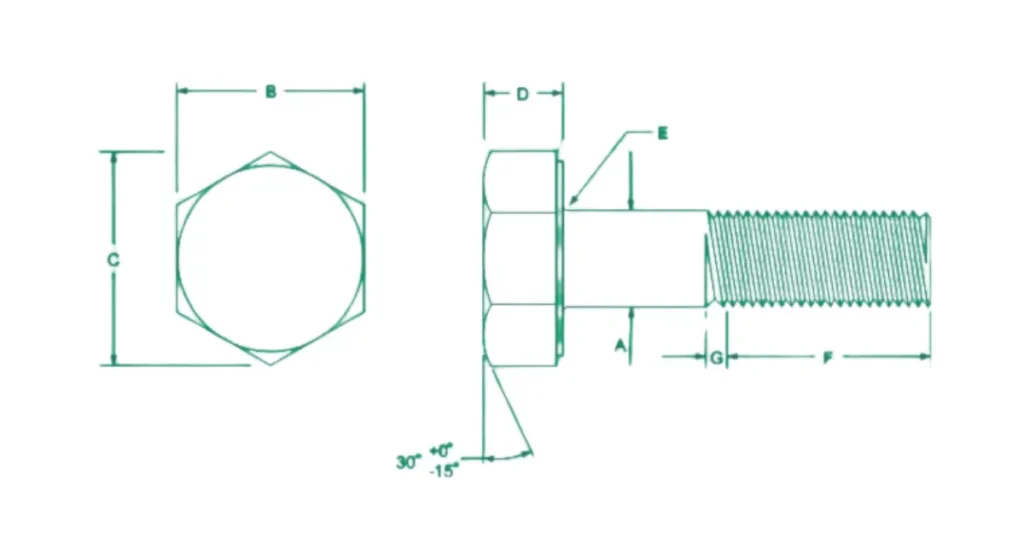

Understanding Bolt Size Notation (Diameter × Pitch × Length)

Before you consult any chart, it helps to decode the three key numbers that define every bolt. First, diameter dictates how much load a fastener can shoulder; a larger shank resists shear, yet it demands a wider hole and heavier tooling.

Next, thread pitch controls how force translates into clamping pressure; a coarse pitch tightens quickly and tolerates dirt, whereas a fine pitch delivers precise preload but risks stripping if installers rush.

Finally, length determines whether the threads engage fully without bottoming out, but excessive overhang wastes material and invites corrosion on exposed threads. Therefore, you must juggle these three variables—diameter, pitch, and length—against space constraints, assembly speed, and long‑term service conditions.

Moreover, each adjustment cascades through the design: switching to a finer pitch may allow higher preload, yet it can force a jump to stronger (and pricier) alloy grades.

Consequently, a well‑structured bolt size chart becomes more than a reference; it clarifies how tweaking one dimension reshapes the entire fastening strategy, ultimately helping you strike the optimal balance between performance, cost, and reliability.

Metric vs. Imperial: Key Differences

Although both metric and imperial systems measure the same physical dimensions, they label and tolerate bolts quite differently. Metric bolts use millimeters for diameter, pitch, and length, offering a straightforward, decimal-based system widely adopted worldwide.

In contrast, imperial bolts list diameter in fractional inches and thread count in threads per inch (TPI), which can complicate conversions and create confusion. This difference forces designers to balance trade-offs: metric bolts simplify global sourcing and reduce errors, but may not fit older equipment designed for imperial fasteners.

Imperial bolts maintain compatibility with legacy tools but limit international options and require careful sizing checks. Additionally, metric and imperial threads follow different tolerance standards, making it crucial to consult a bolt size chart that compares both systems.

Such charts help avoid mismatches, reveal compatible sizes, and guide engineers through challenges when working in mixed-standard environments. Ultimately, understanding these differences ensures the right bolt choice for performance and compatibility.

Standard Metric Bolt Size Chart (M3–M48)

Below is the go‑to reference for common metric bolts, from the tiny M3 used in electronics to the hefty M48 found in heavy machinery. Firstly, smaller sizes like M3 and M4 offer precision and lightweight strength, ideal for delicate assemblies, but they can’t handle heavy loads or harsh environments.

On the other hand, larger bolts such as M24 and above provide exceptional strength and durability, yet they require more space and heavier tools, increasing costs and installation time.

Balancing these factors means selecting a size that meets load requirements without overengineering or overspending. Moreover, pitch variations within each size affect thread engagement and clamping force, so consulting a detailed bolt size chart becomes essential.

This chart not only ensures the right diameter and length but also guides you through pitch choices and strength grades, helping avoid mismatches that compromise safety and performance.

Standard Imperial Bolt Size Chart (¼″–1 ½″)

For projects rooted in U.S. standards, this chart covers the most frequently specified imperial bolt diameters, ranging from ¼″ to 1 ½″. Firstly, smaller sizes like ¼″ and ⅜″ are perfect for light-duty applications, offering ease of installation and cost savings, but they may lack the strength needed for heavy loads.

Conversely, larger diameters such as 1″ and above deliver robust performance in structural and industrial settings, yet they demand more clearance and specialized tools, increasing complexity. Balancing these trade-offs requires careful consideration of load, space, and budget constraints.

Furthermore, thread pitch and grade variations influence the bolt’s holding power and durability. Consulting a detailed imperial bolt size chart helps ensure you select the correct diameter, length, and thread type, ultimately preventing costly mismatches and enhancing overall safety and reliability.

Strength Grades and Head Markings

Those little dashes or digits on a bolt head aren’t decorative—they tell you exactly how much load the fastener can carry. Firstly, understanding these markings helps you choose the right strength grade, balancing durability with cost.

For example, higher-grade bolts can withstand greater stress, but they are often more expensive and may require special tools for installation. On the other hand, lower-grade bolts are cheaper and easier to work with, yet they might fail under heavy loads or harsh conditions.

Therefore, selecting the appropriate grade involves weighing safety requirements against budget and application needs. Moreover, a comprehensive bolt size chart includes strength grades alongside dimensions, making it easier to match the right bolt to your project.

Ultimately, ignoring these markings risks structural failure, while proper attention ensures long-lasting, reliable connections.

Common Mistakes When Reading Size Charts

Misreading pitch or assuming thread compatibility across systems are two of the errors that most frequently lead to stripped threads. Firstly, confusing metric and imperial pitches can cause mismatched threads that damage both bolt and hole, resulting in costly repairs and downtime.

Additionally, overlooking the importance of length can cause bolts to bottom out or fail to engage fully, compromising joint strength. Balancing these factors requires careful attention to detail and a clear understanding of sizing standards.

Furthermore, relying on incomplete or outdated charts increases the risk of errors, especially when dealing with mixed standards or unusual sizes.

Therefore, consulting a comprehensive, up-to-date bolt size chart is crucial—it helps you verify pitch, diameter, and length simultaneously, ultimately preventing common mistakes that jeopardize safety and performance.

Conclusion

With a solid grasp of bolt size charts and the factors surrounding them, you can fasten with confidence on any project. By balancing size, strength, and material, and consulting reliable charts, you avoid costly errors and ensure safety. Ultimately, this knowledge is key to durable, effective fastening solutions.

FAQs

What does the bolt size notation (e.g., M8 × 1.25 × 30) mean?

The notation indicates three key dimensions: diameter (M8 means 8 mm), thread pitch (1.25 mm between threads), and length (30 mm overall). Together, they define the bolt’s size and thread detail to ensure proper fit and strength.

How do I know whether to use metric or imperial bolts?

Choose based on your project’s standards and existing hardware. Metric bolts are common internationally and offer easier sizing, while imperial bolts are typical in the U.S. Compatibility, tooling, and supplier availability also influence the choice.

Why are bolt strength grades important?

Strength grades indicate how much load a bolt can safely carry. Using the correct grade prevents joint failure. Higher grades handle greater stress but can cost more and require specific tools.

Can I mix metric and imperial bolts in the same assembly?

Mixing is generally not recommended due to differences in thread pitch and diameter, which can cause poor fit or damage. Always check compatibility with a detailed bolt size chart.

What are common mistakes when reading bolt size charts?

Common errors include confusing pitch measurements, ignoring length requirements, and not verifying thread compatibility. Using an accurate, comprehensive bolt size chart helps avoid these costly mistakes.