We’ll dive into the world of gas flare fitting sizes, giving you all the information you need to make an informed decision. First, let’s talk about what a gas flare fitting is. Simply put, it’s a device that connects a gas line to a flare stack. It’s an essential component in the oil and gas industry, used to safely and efficiently dispose of excess gas.

Gas flare fittings come in a variety of sizes, ranging from 1/4″ to 6″. The size you need will depend on several factors, including the flow rate of the gas, the pressure of the system, and the diameter of the pipe.

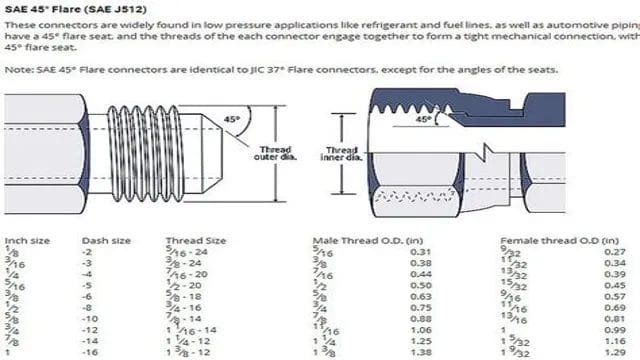

Gas Flare Fitting Size Chart:

| Nominal Size | Female Thread I.D. (In.) | Male Thread O.D. (In.) | No. of Threads Per Inch | Steel Torque Recommended (Ft-Lbs.) |

| 1/8 | 17/64 | 5/16 | 24 | – |

| 3/16 | 21/64 | 3/8 | 24 | – |

| 1/4 | 25/64 | 7/16 | 20 | 10 – 11 |

| 5/16 | 29/64 | 1/2 | 20 | 13 – 15 |

| 3/8 | 9/16 | 5/8 | 18 | 17 – 19 |

| 7/16 | 5/8 | 11/16 | 16 | – |

| 1/2 | 11/16 | 3/4 | 16 | 34 – 38 |

| 5/8 | 13/16 | 7/8 | 14 | 50 – 56 |

| 3/4 | 63/64 | 1 1/16 | 14 | 70 – 78 |

| 1 | 1 13/64 | 1 5/16 | 11 1/2 | 65 |

Overview

When it comes to gas flares, one important consideration is the fitting size chart. This chart will help you determine the appropriate size of the fitting required for your specific gas flare. It’s important to choose the correct size in order to prevent leaks or other issues that could compromise safety and efficiency.

There are a variety of factors to consider when selecting the proper fitting size, including the flare tip size, the pressure of the gas, and the temperature of the system. Some common sizes include 1/2 inch, 3/4 inch, and 1 inch fittings. Your equipment manufacturer or supplier can provide guidance on which size is best suited for your needs.

It’s also important to regularly inspect and maintain your gas flare system to ensure it is functioning properly and adhering to all necessary safety standards.

What is a Gas Flare Fitting?

Gas flare fittings are an essential component in the oil and gas industry. They are used to safely and efficiently burn off gas that cannot be processed or stored. The gas flare fitting is located at the top of a flare stack and is responsible for directing the gas into the stack where it is ignited.

The fitting must be designed to withstand extreme heat, pressure, and corrosive materials. They come in a variety of different sizes and materials to accommodate different types of gas flares. Gas flare fittings are an important safety feature that helps to prevent the release of harmful gases into the environment.

If not for the gas flare fitting, the gas would have to be released directly into the atmosphere, which can have a negative impact on the environment. Keyword: Gas flare fittings

Why is Flare Fitting Size Important?

Flare fitting size is an important aspect to consider when working with hydraulic systems, as it can have a significant impact on the overall effectiveness and safety of the system. The size of the flare fitting refers to the diameter of the tubing that is used to connect different components of the hydraulic system together. It is crucial to choose the correct size of flare fitting to ensure that the system can function properly and deliver the required levels of pressure and flow.

If the flare fitting size is too small, it can cause issues such as restricted flow and pressure drop, which can impede the performance of the system. Conversely, if the fitting is too large, it can create leaks, which can be hazardous to the operator and damage the system. Therefore, selecting the appropriate flare fitting size is crucial for ensuring that a hydraulic system performs at its best.

How to Read the Chart

If you’re making use of a gas flare fitting size chart, it’s crucial to understand how to read it properly. The chart is typically organized into rows and columns, with the fittings’ dimensions listed in the rows and the different types of fittings in the columns. The dimensions of the fittings are usually given in inches, and it’s important to ensure that you select the right size for your particular application.

One of the most important things to consider when choosing a fitting size is the burstiness of the gas you will be working with. This refers to the pressure at which the gas will be released from the fitting, and it’s crucial to choose a fitting that can handle this pressure without bursting. Another key factor to consider is the perplexity of the gas, which refers to the pressure changes that can occur in the system over time.

By understanding these factors and interpreting the gas flare fitting size chart correctly, you can avoid potentially dangerous situations and ensure that your gas system runs smoothly and reliably.

Understanding Fitting Size Measurements

When it comes to finding the perfect fit, it’s crucial to understand fitting size measurements. This is where fitting size charts come in handy. But how do you read them? Let’s break it down.

The first thing you should know is that each brand may have its own unique sizing chart, so it’s essential to refer to the one provided by the brand you’re interested in. Once you have the chart, look for the corresponding categories such as bust, waist, hips, and inseam. Each category will have a range of measurements in inches or centimeters.

To find the right size for you, measure yourself using a tape measure or compare your measurements to the chart’s range. Keep in mind that not all brands will have the same fit, so it’s always best to try on the item before purchasing. With these tips, you’ll be able to decode fitting size charts and find the perfect fit for your body.

Interpreting the Chart

Reading the chart can be daunting at first, but once you understand its format, it becomes much simpler. The chart is typically divided into two axes: the x-axis and the y-axis. The x-axis represents the independent variable, while the y-axis represents the dependent variable.

The independent variable is the one being tested and manipulated, while the dependent variable is the one being measured. Each axis is then labeled with units of measurement, such as time or frequency. The data is plotted on the chart using dots or lines that connect the dots.

The dots or lines are then labeled to clearly show which data set they represent. To understand the chart, you need to interpret the patterns and trends that emerge from the data. You can do this by examining the shape of the chart, the slope of the lines, and the distance between data points.

By doing so, you can draw conclusions about the data and understand the relationship between the independent and dependent variables. Overall, becoming comfortable with reading charts takes practice, but it is an important skill for understanding and communicating data effectively.

Finding Your Fitting Size

If you are looking for the right gas flare fitting size chart, it is important to first know what size you need. A gas flare fitting is a crucial component of a gas system and ensuring the correct size is vital for safety and efficiency. To determine the proper size, there are a few steps you can take.

The first is to measure the outer diameter of the flare. This is the widest part on the outside of the fitting. Next, measure the diameter of the pipe or tube you will be connecting it to.

After obtaining these measurements, you can use a gas flare fitting size chart to match the correct size. It’s important to note, using the wrong size fitting can lead to gas leaks and other hazards. To ensure you have the correct size, it is always recommended to consult with a professional.

By taking the proper steps and using a size chart, you can ensure the safety and effectiveness of your gas system.

Steps to Determine Fitting Size

Determining the right fitting size can be a daunting task, especially if you’re ordering online or trying on different types of clothes. However, it’s crucial to find your fitting size to ensure comfort and prevent any wardrobe malfunctions. Here are a few steps you can take to determine your fitting size:

Measure yourself accurately: Take measurements of your chest, waist, hips, and inseam to get a clear idea of your body’s size and shape. Check the brand’s size chart: Different brands have varying size charts, so make sure to check the brand’s size chart before making a purchase.

Consider your body type: If you have a pear-shaped body, you may need a larger size at the bottom, whereas an apple-shaped body may require a larger size at the top.

Try on different sizes: Don’t be afraid to try on a few different sizes to find the right one. Remember, the goal is to find a size that fits comfortably and accentuates your body shape. Taking these steps can help you find the perfect fitting size, whether you’re shopping for everyday clothes or formal wear.

By taking the time to find your fitting size, you’ll undoubtedly feel confident and comfortable in every outfit you wear!

Common Fitting Sizes for Different Applications

When it comes to fittings, it can be quite daunting to figure out which size will work best for your specific application. Luckily, common fitting sizes exist for different types of applications. For example, when it comes to plumbing, the most common sizes for fittings are 0.

5 inch and 0.75 inch. In automotive applications, fitting sizes can range anywhere from 1/8 inch to 2 inches in diameter, depending on the specific component being used.

It’s important to properly measure your application to ensure you find the right fitting size to ensure a secure and tight fit. Additionally, it’s important to consider the type of material the fitting is made from and how it will handle corrosion, temperature changes, and pressure. By taking all of these factors into consideration, you can find the right fitting size for your application, ensuring your project is a success.

Conclusion

In conclusion, the gas flare fitting size chart is like a roadmap to the land of efficient and safe gas flaring. With the right size fitting, you can prevent leaks, decrease emissions, and improve your overall operations. So, take a moment to peruse the chart, find your perfect fit, and let your gas flares shine with brilliance and precision.

Remember, size does matter, especially when it comes to gas fittings!

FAQs

What is a gas flare fitting?

A gas flare fitting is a type of piping connection used to safely release excess gas pressure in industrial settings.

How do I determine the correct size for a gas flare fitting?

The size of a gas flare fitting is determined by the diameter of the pipe, so consult a gas flare fitting size chart to find the appropriate size for your application.

What materials are gas flare fittings typically made from?

Gas flare fittings are commonly made from materials like stainless steel or carbon steel that can withstand high pressures and temperatures.

Can gas flare fittings be customized for specific applications?

Yes, gas flare fittings can be customized to fit specific pipe sizes and to meet unique pressure and temperature requirements. Consult with a professional to determine the best options for your needs.