Navigate the world of cylindrical roller bearings with ease using our guide to deciphering the size chart. These bearings are crucial for industrial machinery, providing support and enabling smooth movement while resisting loads. With our help, you’ll understand how to interpret the chart’s inner and outer diameter, width, and angle of contact, ensuring you choose the right bearing for your application.

Don’t let the complexity overwhelm you—let’s explore the world of bearings together!

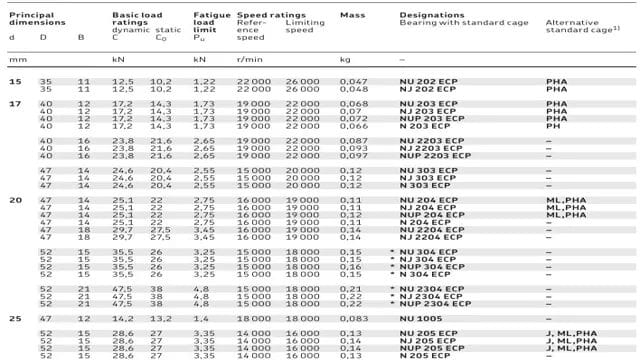

Cylindrical Roller Bearing Size Chart

| SL No. | Bearing No. | d (mm) | D (mm) | B (mm) | r (min) | Basic Dynamic Load Rating (Cr) | Basic Static Load Rating (Cor) | Limiting Speed (min^-1) Grease Lubrication | Limiting Speed (min^-1) Oil Lubrication | Mass (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 295 | NJ 2318 | 90 | 190 | 64 | 3 | 325000 | 395000 | 2800 | 3600 | 7.9 |

| 294 | NJ 2316 | 80 | 170 | 58 | 2.1 | 274000 | 330000 | 3200 | 4000 | 5.83 |

| 293 | NJ 2315 | 75 | 160 | 55 | 2.1 | 258000 | 300000 | 3400 | 4300 | 4.84 |

| 292 | NJ 2313 | 65 | 140 | 48 | 2.1 | 188000 | 212000 | 4000 | 4800 | 3.25 |

| 291 | NJ 2311 | 55 | 120 | 43 | 2 | 148000 | 162000 | 4800 | 5600 | 2.1 |

| 290 | NJ 2310 | 50 | 110 | 40 | 2 | 121000 | 131000 | 5400 | 6500 | 1.69 |

| 289 | NJ 2309 | 45 | 100 | 36 | 1.5 | 99000 | 104000 | 6100 | 7300 | 1.25 |

| 288 | NJ 2308 | 40 | 90 | 33 | 1.5 | 82500 | 88000 | 6500 | 7800 | 0.956 |

| 287 | NJ 2307 | 35 | 80 | 31 | 1.5 | 60500 | 60000 | 7200 | 8600 | 0.696 |

| 286 | NJ 2306 | 30 | 72 | 27 | 1.1 | 51500 | 51000 | 8200 | 9800 | 0.5 |

What are Cylindrical Roller Bearings?

If you’re unfamiliar with cylindrical roller bearings, they’re a type of rolling element bearing that uses cylinders to help reduce friction between moving parts. But what is a cylindrical roller bearing size chart, and why is it important? Essentially, a size chart allows you to quickly and easily find the correct bearing size for your particular application. This is crucial because choosing the wrong size can result in poor performance or even failure of your machinery.

Size charts typically include information such as bore diameter, outer diameter, and width. By using this information to select the correct bearing size, you can ensure optimal performance and long-lasting durability. So whether you’re an engineer designing a new piece of equipment or a mechanic replacing a worn-out bearing, a cylindrical roller bearing size chart can be an invaluable tool in your arsenal.

Description and Function

Cylindrical roller bearings are a type of rolling-element bearing that have cylindrical rollers instead of balls. They are designed to carry heavy loads and can handle both radial and axial loads. Cylindrical roller bearings are widely used in various industries such as automotive, mining, and construction, among others.

They come in different designs, such as single-row, double-row, and high-capacity. Single-row cylindrical roller bearings have a cage, which separates the rollers and keeps them in position. Double-row cylindrical roller bearings, on the other hand, have two sets of rollers and are designed to handle heavier loads.

High-capacity cylindrical roller bearings are used for applications where high radial loads are present. They have larger rollers and higher load ratings compared to standard cylindrical roller bearings. Cylindrical roller bearings are essential components in machinery and equipment that require high accuracy and stability.

They play a crucial role in ensuring the smooth and efficient operation of industrial applications.

Types of Cylindrical Roller Bearings

Cylindrical roller bearings are a type of rolling element bearing that helps support high radial loads. They have a cylindrical shape and are commonly used in machines such as construction equipment and agricultural machinery. There are several types of cylindrical roller bearings, including single-row, double-row, and multi-row bearings.

Single-row bearings are the most basic and have a single row of cylindrical rollers. Double-row bearings have two rows of cylindrical rollers that are arranged perpendicular to each other, allowing for increased radial load capacity. Multi-row bearings have three or more rows of cylindrical rollers that are arranged parallel to each other and can support even higher radial loads.

It is important to select the correct type of cylindrical roller bearing for a specific application in order to ensure optimal performance and longevity.

Why is a Size Chart Important?

When it comes to choosing the right cylindrical roller bearing for your machinery, having access to a reliable size chart is crucial. This chart serves as a guide to ensure that you choose the right size for your specific application. A size chart provides the necessary dimensions such as bore diameter, outer diameter, and width measurements.

Having this information at your fingertips can help you avoid costly mistakes that may result in downtime, machinery damage, or even personal injury. With a properly designed and accurate size chart, you can confidently select the right cylindrical roller bearings for your machinery. Size charts also help to prevent confusion or misunderstandings since bearing manufacturers often use different terminology or measurement units.

Therefore, keeping a size chart at hand can help you make informed decisions and save time and money in the long run. So, always ensure that your size chart is updated and accurate, especially when selecting a cylindrical roller bearing for your machinery.

Understanding Roller Bearing Sizes and Codes

As we all know, roller bearings are crucial in various machines and devices that require smooth and efficient movements. However, selecting the right size and code can be a daunting task, especially for those who are not familiar with the technicalities of roller bearings. This is where a size chart comes in handy.

It provides a comprehensive guide on the specifications of roller bearings, making it easier for users to select the appropriate size and code for their machine or equipment. With a size chart, you can easily identify the inner and outer diameter, width, and other essential measurements of roller bearings, helping you find the perfect match for your needs. When using a size chart, it is important to pay attention to the codes as well.

These codes often signify the type of bearing, the materials used, and other distinguishing characteristics that may affect its performance. By understanding roller bearing sizes and codes through a size chart, you can be confident in choosing the right one, saving yourself time and money in the long run.

Factors to Consider When Selecting the Right Size

When it comes to purchasing new clothing, selecting the right size is crucial for a comfortable and flattering fit. This is where a size chart becomes essential. Size charts provide the necessary measurements for determining which size will fit you best.

They can vary between brands and even between different clothing items within the same brand, so it’s crucial to refer to the size chart specific to the item you’re purchasing. Keep in mind that not every brand’s sizing will be the same, so taking the time to consult the size chart before making a purchase can save you the hassle of returns or ill-fitting clothing. Therefore, it’s essential to have a clear understanding of your body measurements and refer to a size chart as a guide to ensure you select the right size and achieve the best fit possible.

Common Sizes for Various Applications

“size chart” A size chart is an essential tool that helps to determine the appropriate size for a specific product. It is vital to understand that various manufacturers have different sizing charts, and that’s why it’s essential to refer to the manufacturer’s size chart when purchasing a product. For instance, when buying clothes, it’s essential to check the size chart to get the right fit.

The same applies when purchasing shoes, hats, gloves, and other accessories. A size chart is also important when buying online, as one can’t try on the item before purchasing. A well-designed size chart must include detailed measurements, such as waist, chest, hips, and inseam, among others.

In conclusion, a size chart is critical in ensuring that customers make informed purchasing decisions, which ultimately results in better customer satisfaction as they receive a product that fits properly.

How to Read a Cylindrical Roller Bearing Size Chart

Reading a cylindrical roller bearing size chart may seem daunting at first glance, but with a little knowledge, it becomes a breeze. The first thing to note on the chart is the bearing’s dimensions. This typically includes the bore, outside diameter, and width.

The bore refers to the inner diameter of the bearing, while the outside diameter measures the outer circumference. The width is the length of the bearing from one side to the other. Cylindrical roller bearings may have different load capacities, speed limits, and designs, so it’s also essential to look for these values on the chart.

The chart may also indicate whether the bearing has a single or a double row of rollers. The more rollers a bearing has, the higher its load capacity and the smoother its operation. In summary, understanding the dimensions, load capacity, and roller design on a cylindrical roller bearing size chart is vital in selecting the right bearing for your application.

Explanation of Columns and Measurements

When it comes to reading a cylindrical roller bearing size chart, it can look confusing at first. However, it’s actually pretty simple once you understand the different columns and measurements. The first column typically shows the part number, which is specific to that particular bearing.

The second column shows the bore size or the inner diameter of the bearing. This is important because it needs to fit properly on the shaft. The third column shows the outside diameter, which is the total diameter of the bearing.

The fourth column shows the width, or thickness, of the bearing. Finally, the fifth column shows the dynamic load rating and the sixth column shows the static load rating. These ratings indicate the maximum load the bearing can withstand before failure.

Overall, understanding how to read a cylindrical roller bearing size chart is essential for selecting the right bearing for your application. By paying attention to the different measurements and ratings, you can ensure that your bearings will perform properly and last as long as possible.

Examples and Application Scenarios

When it comes to reading a cylindrical roller bearing size chart, it’s important to keep in mind the dimensions and measurements indicated. The chart will typically display the bearing type, bore diameter, outside diameter, overall width, and dynamic load capacity. These size specifications play a crucial role in ensuring that the bearing can effectively handle the intended load and rotation speed.

For example, a larger bearing size may be necessary for high-speed applications, while a smaller size may be more suitable for lower speeds. Additionally, understanding the bearing type is important, as this will determine its specific design features and intended use. With all these factors in mind, effectively reading and interpreting a cylindrical roller bearing size chart can help ensure optimal performance and longevity of the bearing in various application scenarios.

Where to Find and Download Size Charts Online

When it comes to finding and downloading size charts for cylindrical roller bearings online, there are a few reliable sources you can turn to. One great option is the website of the bearing manufacturer itself – many companies will have downloadable size charts for their different bearing models available on their websites. Another option is to search for bearing distributors online, as they often provide size charts and other helpful resources for those looking to purchase bearings.

You can also check out online forums and communities for mechanical engineers and other professionals who work with bearings, as they may have resources or recommendations for helpful size charts. By taking the time to research and download size charts for cylindrical roller bearings, you can ensure that you have the information you need to make informed decisions about which bearings to purchase for your specific applications.

Conclusion

In conclusion, navigating the world of cylindrical roller-bearing sizes can be a daunting task. With so many options available, it’s easy to get lost in the sea of numbers and technical jargon. But fear not, dear reader! Just like how Goldilocks found the perfect bowl of porridge, there is a cylindrical roller bearing size that is just right for every application.

So don’t settle for a bearing that’s too big or too small, use the size chart as your guide and find the perfect fit for your machinery. After all, the right bearing is the key to a smooth and successful operation. Cheers to finding the right fit!

FAQs

What is a cylindrical roller bearing?

A cylindrical roller bearing is a type of rolling-element bearing that uses cylinders (rollers) to support and guide a rotating shaft.

What are the advantages of using cylindrical roller bearings?

The advantages of using cylindrical roller bearings include high load capacity, low friction, and ability to handle radial and axial loads.

How are cylindrical roller bearings sized?

Cylindrical roller bearings are sized based on the diameter of the outer and inner rings, as well as the width of the bearing itself.

What is the difference between a single-row and double-row cylindrical roller bearings?

A single-row cylindrical roller bearing has a single row of rollers, while a double-row cylindrical roller bearing has two rows of rollers, which can handle higher radial loads.