If you’re a cycling enthusiast, you’re likely aware of the importance of bicycle ball bearings. These small components play a crucial role in keeping your bike running smoothly, with less friction and better performance. But with so many types and sizes available, how do you choose the right one for your bike? Luckily, a bicycle ball bearing size chart can help you find the perfect fit.

So, next time you need to replace your bike’s ball bearings, consult the chart and select the proper size for optimal performance.

Importance of Ball Bearings in Bicycles

Ball Bearings in Bicycles When it comes to bicycles, ball bearings play a crucial role in ensuring a smooth and efficient ride. These small, metal spheres are fitted within the bike’s wheel hubs, pedals, headset, and bottom bracket, acting as a buffer between moving parts. The importance of ball bearings lies in their ability to reduce friction and wear between these components, preventing premature wear and tear.

When neglected or improperly maintained, ball bearings can become damaged, leading to increased rolling resistance, poor handling, and even dangerous accidents. By choosing quality ball bearings and regularly servicing your bike, you can ensure a safer and more enjoyable ride.

Bearing Size Chart

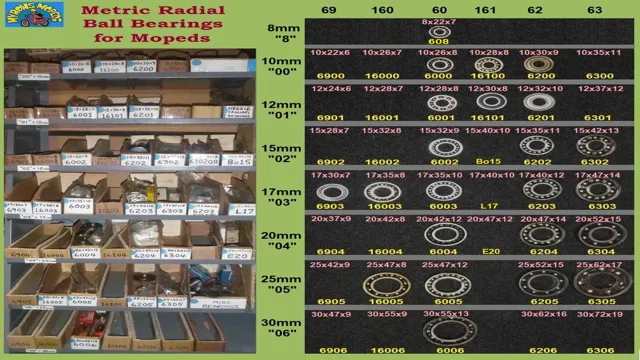

If you’re maintaining or upgrading your bike’s performance, it’s important to know the right bearing size. A bicycle ball bearing size chart can help you determine the correct bearing size for your wheels, headset, or bottom bracket. The sizes are typically measured in metric units, such as millimeters, and can vary depending on the type of bike or component.

It’s crucial to use the correct size bearing to ensure smooth operation and prevent damage to your bike. To find the correct size, you can refer to the manufacturer’s specifications or consult a bike mechanic. Don’t forget to regularly check and replace your bearings to maintain optimal performance and prolong the lifespan of your bike.

Understanding Bearing Sizes

If you’re new to the world of bearings, understanding bearing sizes can be overwhelming. Thankfully, there is a bearing size chart that can help you decode the numbers and letters that signify a specific bearing size. The chart typically lists the inner and outer diameter, as well as the width or depth of the bearing, and may also include the type of bearing, such as ball bearings, roller bearings, or needle bearings.

For example, a bearing size of 6003-2RS would indicate a ball bearing with an inner diameter of 17mm, outer diameter of 35mm, and width of 10mm. It’s important to note that different manufacturers may have slight variations in their bearing size designations. Familiarizing yourself with the bearing size chart can help ensure you select the correct bearing for your specific application.

Components of Bearing Sizes

When it comes to bearings, there are various sizes available to suit different applications. A bearing size chart usually includes the dimensions, load ratings, and other specifications for each size. The dimensions of a bearing typically refer to its inner diameter, outer diameter, and width.

Load ratings indicate the maximum load a bearing can handle, which is essential to ensure longevity and reliability. Some other factors that can affect bearing sizes include material, design, and lubrication. It’s essential to choose the right size and type of bearing for your machine or equipment to ensure optimal performance and durability.

Using a bearing too small or too large can cause premature wear and tear, lowering the lifespan of the bearing and potentially causing damage to the machine. By referring to a bearing size chart and consulting with a bearing expert, you can select the ideal bearing size for your application, maximizing efficiency and minimizing operational costs.

How to Measure Ball Bearings

If you’re into bicycles, then you understand that ball bearings are vital components of the wheel and crankset. However, choosing the correct bicycle ball bearing size can be a difficult task. To do that, you need to measure the ball bearing’s inner diameter, outer diameter, and width.

The easiest way to measure a ball bearing is to look up its size chart online or in the manufacturer’s manual. The bicycle ball bearing size chart will list the standard sizes available and help you choose the one that fits your bike’s needs. Just remember to measure your ball bearings correctly, or you might end up with the wrong size, leading to a poor riding experience.

So make sure to take your time and measure everything correctly to ensure a smooth ride every time you hit the road.

Step-by-Step Guide to Measuring Bearings

Measuring ball bearings might seem like a daunting task, but it’s essential for ensuring the proper functioning and longevity of your equipment. First and foremost, make sure to clean the bearings thoroughly before measuring them. Next, use a digital caliper to measure the outside diameter of the bearing, taking care to measure at the widest point.

From there, measure the inside diameter by placing the caliper arms inside the bearing and gently closing them until they make contact. Make sure to take note of any ridges or uneven surfaces that might affect your measurements. Finally, measure the height or thickness of the bearing.

With these three measurements in hand, you should be able to find a replacement bearing with ease. Remember, accuracy is key, so take your time and make sure your measurements are as precise as possible.

Different Types of Ball Bearings

One of the most integral parts of any bicycle is its ball bearings. These tiny components greatly affect the overall performance of your bike. However, with a variety of different types of ball bearings available in the market, it can be challenging to select the ideal one for your bike.

The most common types of ball bearings used in bicycles are steel, ceramic, and hybrid. Steel ball bearings are the most affordable and provide excellent durability, while ceramic bearings are more expensive but offer better performance and less friction. Hybrid bearings are a blend of steel and ceramic and provide a balance between durability and performance.

To ensure that you choose the correct size of ball bearing, it’s important to refer to a bicycle ball bearing size chart, as the dimensions vary between different types of bikes. By selecting the right type and size of ball bearings for your bike, you can help to improve its overall speed and efficiency, providing a smoother, more enjoyable ride.

Deep Groove Ball Bearings

When it comes to ball bearings, not all are created equal. Deep groove ball bearings, for instance, are a type of ball bearing that boasts a sleek and thin design, making them ideal for high-speed applications. These bearings are often used in machines that run at incredibly high speeds, such as turbines and electrical motors.

Deep groove ball bearings come in a variety of materials such as stainless steel and ceramic, with each type catering to different needs and requirements. One advantage of using deep groove ball bearings is that they have a higher load capacity compared to other ball bearing types. Understanding the different types of ball bearings and their applications is essential in finding the right bearings for your machinery.

By choosing the right type of ball bearings, you can ensure optimal performance and longevity for your machines.

Angular Contact Ball Bearings

Angular Contact Ball Bearings Ball bearings are commonly used in different machines, from mechanical to electronic devices. These bearings are essential components that reduce friction between rotating parts, resulting in better performance and longer service life. Among the different types of ball bearings, angular contact ball bearings are highly versatile and can withstand both radial and axial loads.

These bearings have a contact angle that enables them to support axial loads in one direction, and they offer high precision and stiffness in various applications. There are several variations of angular contact ball bearings, including single-row, double-row, and four-point contact bearings. Each type has its own unique design and performance characteristics suitable for different applications, such as automotive, aerospace, and medical equipment.

Overall, angular contact ball bearings play a vital role in improving the performance and efficiency of various machines and equipment.

Thrust Ball Bearings

Thrust ball bearings are a type of ball bearings that are commonly used in applications that involve axial loads. They typically consist of two washers and a set of balls that are arranged in a cage. One of the washers is designed to be fixed in place, while the other is free to rotate.

When a load is placed on the bearing, the balls roll along the raceway between the two washers, allowing them to rotate. This type of bearing is commonly used in automotive applications, as well as in machinery that requires high-speed rotation. There are several different types of thrust ball bearings available on the market, including single-directional bearings, double-directional bearings, and bi-directional bearings.

Each type of bearing is designed to be used in a specific type of application, so it’s important to choose the right one for your needs.

Self-Aligning Ball Bearings

Self-Aligning Ball Bearings Ball bearings are vital components of any rotating machinery, and they come in various types. Self-aligning ball bearings are among the most common types and provide excellent features that enhance their functionality. These bearings use two rows of balls that run on separate raceways, one with a spherical outer ring and the other with a concave inner ring, which allows for misalignment compensation.

Self-aligning ball bearings can tolerate misalignment, shaft deflections, and other types of deformations without affecting their performance. They are ideal for use in applications where high speeds, low friction, and low noise levels are essential. Moreover, self-aligning ball bearings are available in different sizes, designs, and materials to accommodate diverse application requirements.

They are widely used in industries such as agriculture, automotive, construction, and mining, among others. Overall, self-aligning ball bearings are reliable and cost-effective components that provide high-performance levels, durability, and easy maintenance.

Conclusion

So, after all that technical jargon and numbers, you may be wondering why the size of your bicycle ball bearings even matters. Well, let us put it simply – ball bearings are the unsung heroes of your bike’s smooth operation. Just like how the right size and spacing in a dance partner can make all the difference in a graceful waltz, the correct size and fit of your bike’s ball bearings can make for a seamless ride.

So, whether you’re a casual cyclist or a hardcore racer, pay attention to those little balls rolling around inside your bike – they’re the true MVPs of your ride.”

FAQs

What is a ball bearing in a bicycle?

A ball bearing is a vital component in a bicycle wheel that helps reduce friction and ensure smooth wheel rotation.

How important is the size of a ball bearing in a bicycle?

The size of a ball bearing in a bicycle is crucial to the bike’s performance. If the size isn’t correct, it may cause wear and tear on the wheel, leading to poor bike handling.

How can I determine the size of the ball bearing I need for my bicycle?

To determine the size of the ball bearing needed for your bicycle, you need to measure the inner and outer diameter of the wheel axle and bearing cup. You can then match those measurements with a bicycle ball bearing size chart.

Which ball bearing material is ideal for a bicycle?

For most bicycles, steel ball bearings are the best material due to their durability and resistance to wear. However, ceramic ball bearings are becoming more popular due to their improved performance and longer lifespan in extreme conditions.